Exploring the mechanisms of a Scotch tension spinning wheel becomes exciting because this tool brings a remarkable control and finesse to your yarn craft, enhancing the quality and versatility of the resulting yarns.

Key takeaways:

- Scotch tension system provides precise control for even spinning.

- Components include brake band, tension knob, and spring/elastic band.

- Adjust tension by turning knob clockwise/counterclockwise.

- Troubleshoot slipping drive band, inconsistent yarn thickness, yarn breakage, bobbin overfilling, and tension not holding.

- Scotch tension allows for versatile yarn weights and types.

What Is a Scotch Tension System?

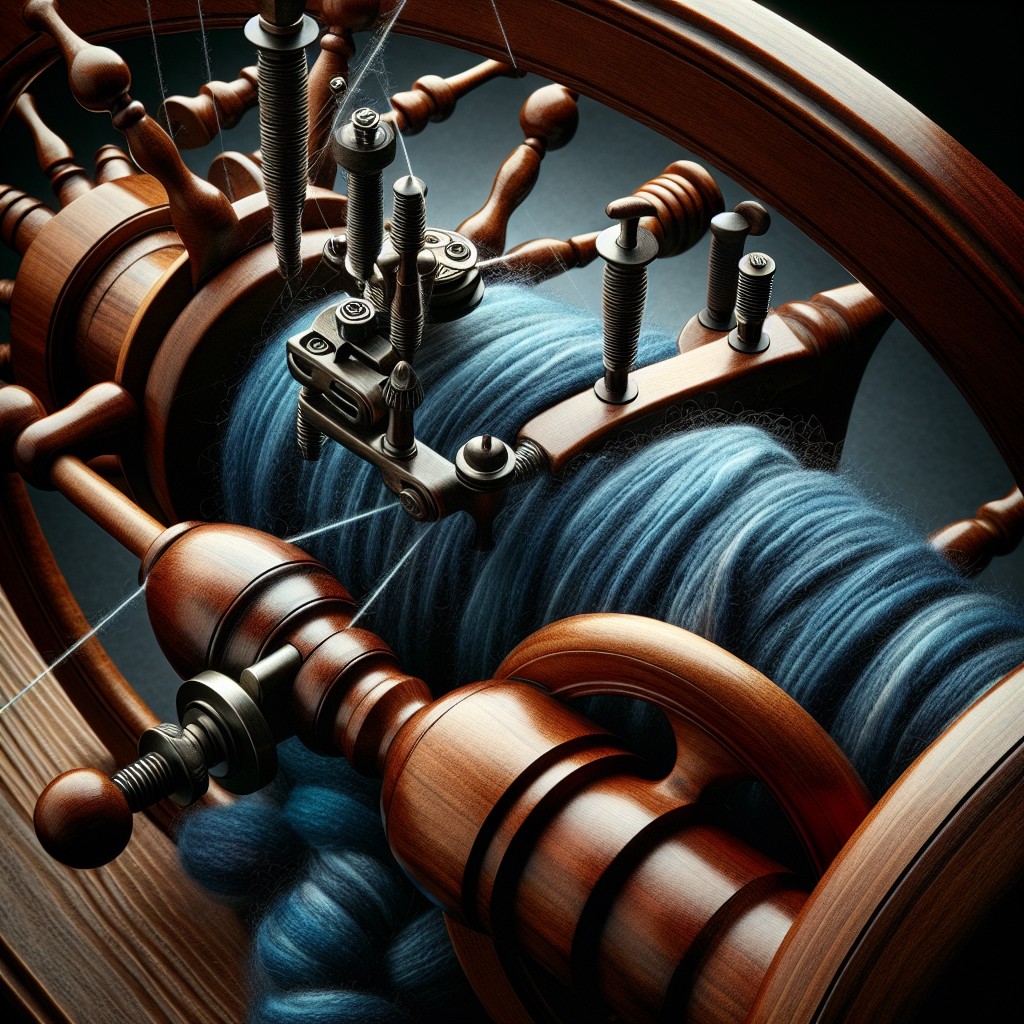

The Scotch tension system, a staple for many spinners, relies on a single drive band that powers the flyer, with a separate brake band adding adjustable resistance to the bobbin. This design allows for precise control of the yarn take-up speed, contributing to the creation of evenly spun yarns across various thicknesses.

Ideal for fine spinning and plying, it provides a delicate balance of forces that result in a smooth spinning experience that many artisans cherish. This system’s hallmark is the ability to fine-tune the tension via a simple knob or screw, granting spinners the flexibility to adapt to different fibers and spinning styles with ease.

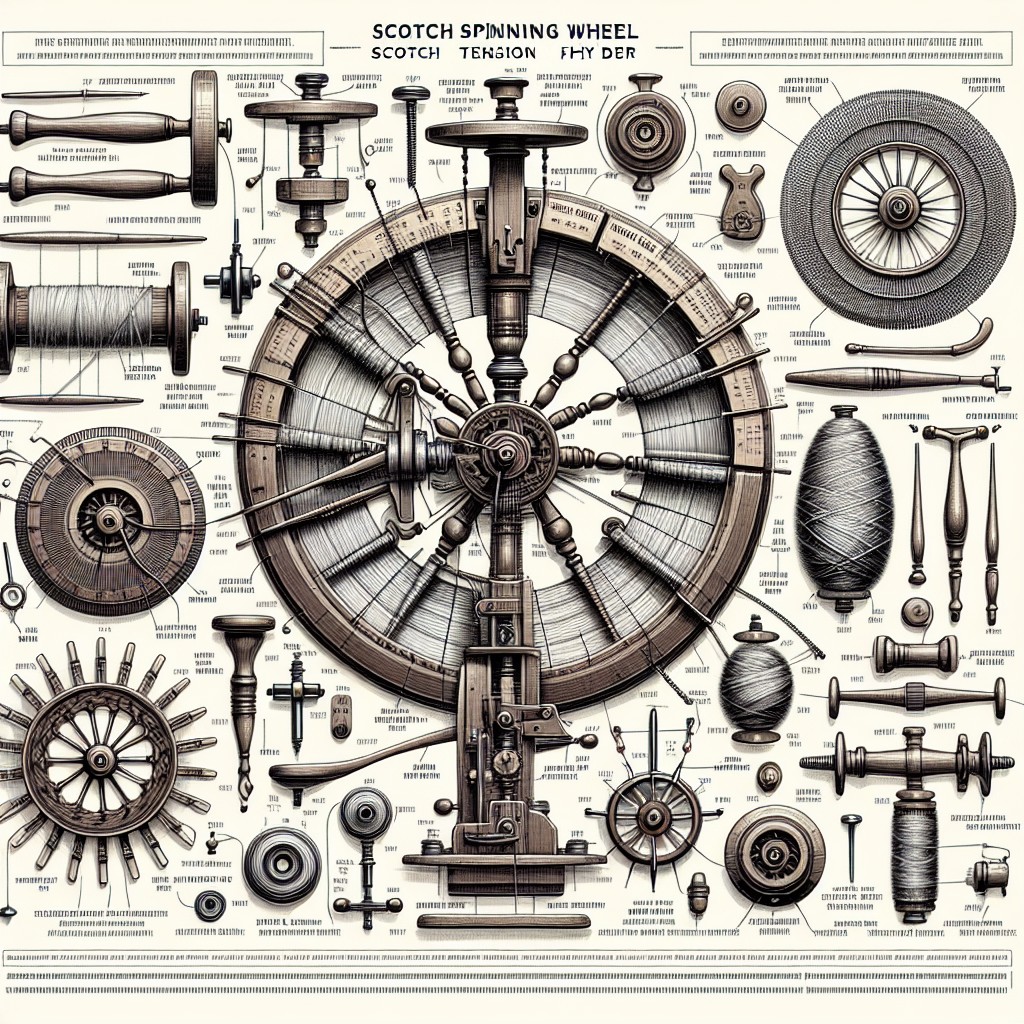

Components of the Scotch Tension System

The Scotch tension system primarily consists of three elements that work together to control the amount of pull on the yarn as it’s wound onto the bobbin:

1. Brake Band: A simple string or band that wraps around the bobbin’s whorl, creating friction to regulate the yarn take-up.

2. Tension Knob: Attached to one end of the brake band, this knob allows spinners to finely adjust the tension by tightening or loosening the brake band.

3. Spring or Elastic Band: Connected to the other end of the brake band, providing a consistent amount of pull, which helps to maintain even tension throughout the spinning process.

Understanding these components and their interaction is crucial for achieving consistent yarn thickness and preventing breakage or overspinning.

Adjusting Scotch Tension

Achieving the desired yarn twist and thickness requires fine-tuning your spinning wheel’s tension. To adjust the Scotch tension:

1. Locate the tension knob or screw attached to a small spring or elastic band exerting pressure on the bobbin’s brake band.

2. Turn the knob clockwise to increase tension, which will slow down the bobbin and add more twist to the yarn.

3. Conversely, turn the knob counterclockwise to decrease tension, allowing the bobbin to rotate faster, producing less twist and a thicker yarn.

4. Make small adjustments and test by treadling and feeding fiber to assess the yarn’s formation.

5. Aim for a balance where the bobbin collects the yarn consistently, but the wheel does not pull the fiber out of your hands too aggressively.

Remember, environmental factors can affect the tension, so recheck and adjust as needed during your spinning session.

Advantages of Scotch Tension Spinning Wheels

Scotch tension spinning wheels offer fine control over the amount of brake applied to the bobbin, allowing spinners to effortlessly adjust the take-up of yarn. This precise tension adjustment is particularly beneficial when spinning fine yarns or working with delicate fibers that require a gentle touch. The system makes it easier to achieve a consistent yarn thickness, which is invaluable for projects requiring uniformity.

Due to the independent control over the drive band and brake system, spinners can manipulate the twist and take-up separately, opening up possibilities for creating a wide range of yarn styles from a single wheel. Beginners find Scotch tension user-friendly since it simplifies the learning process, making it less likely for new spinners to be overwhelmed.

Moreover, Scotch tension is ideal for plying. The fine control over tension prevents over-twisting and helps maintain a balanced yarn. The system is also low-maintenance and usually involves simple adjustments like tightening or loosening a single piece, such as a fishing line or a small knob, contributing to the ease of use and upkeep.

Troubleshooting Common Scotch Tension Issues

If you encounter difficulty with your Scotch tension spinning wheel, here are a few common issues and solutions:

1. Slipping Drive Band: Ensure the drive band is properly positioned and has the correct tension. If it’s too loose, it may require tightening or replacement if it’s worn.

2. Inconsistent Yarn Thickness: Adjust the brake band tension to apply more or less pull on the bobbin. This helps control the take-up of the yarn for more consistent results.

3. Yarn Breakage: This often results from too much tension. Ease the brake band slightly to reduce the pull on the yarn as it winds onto the bobbin.

4. Bobbin Overfilling: Move the yarn guide regularly to distribute yarn evenly across the bobbin. If overfilling persists, check for any blockages and clear them to ensure smooth yarn feed.

5. Tension Not Holding: If the tension knob loosens during spinning, try adding a washer or a lock nut to secure it in place.

Remember, minor adjustments can make a big difference. It’s best to make small changes and test the results as you go.

Comparing Scotch Tension With Other Tension Systems

Understanding the differences between Scotch tension and other tension systems helps spinners choose the right wheel for their projects. Double drive and Irish tension are two common alternatives, each with unique characteristics:

Double Drive:

- In a double drive system, both the flyer and the bobbin are driven by a single, continuous drive band looped twice.

- This creates a balanced pull on both flyer and bobbin, offering consistent speed and tension ideal for experienced spinners desiring precision and control.

- It requires a delicate balance; adjustments can be more complex than with Scotch tension.

Irish Tension:

- Also known as bobbin lead, the drive band in Irish tension only turns the bobbin, while the flyer is slowed by brake action.

- Here, the pull is stronger on the bobbin than on the flyer, which can be advantageous when spinning thicker, bulkier yarns.

- Irish tension spinning wheels are often simpler to adjust but offer less fine control over the take-up than Scotch tension.

Each system has its learning curve and suitability for different types of yarn. Scotch tension is celebrated for its versatility, allowing for a wide range of yarn weights and types with simple tension adjustments. In contrast, double drive and Irish tension systems may require more experience but offer advantages for specific spinning styles.

Maintenance of Scotch Tension Spinning Wheels

Keeping your Scotch tension spinning wheel in prime working order ensures a smooth spinning experience. Regular maintenance involves minimal, but specific, tasks:

- Tension Cord Inspection – Examine the tension cord for any signs of wear or fraying. Replace if necessary, as a damaged cord can affect the consistency of your yarn.

- Spring Care – Check the integrity of the tension spring. It should provide enough resistance to regulate the tension. If it appears stretched or deformed, it’s time for a replacement.

- Flyer Hooks – Ensure that the flyer hooks are not bent or broken, as this can cause the yarn to snag or break. If they are damaged, they should be gently bent back into place or replaced.

- Lubrication – Lubricate moving parts according to your wheel manufacturer’s recommendations. A drop of oil can keep the wheel spinning smoothly without unwelcome noise or extra effort.

- Cleanliness – Remove any lint, fiber, or dust that accumulates around the wheel’s moving parts. This debris can interfere with the function of the wheel if left unattended.

- Storage – When not in use, store your wheel in a dry, safe place to avoid any accidental damage or warping of its components from humidity.

By adhering to these maintenance tips, you can preserve the life of your Scotch tension spinning wheel and enjoy many years of crafting beautiful yarns.

FAQ

What is Scotch tension in spinning?

Scotch tension in spinning is a technique where a tension peg and spring are used to adjust the pull on the yarn, allowing for its controlled draw onto the bobbin.

What is Irish tension on a spinning wheel?

Irish tension on a spinning wheel is a single-drive tension system where the bobbin turns faster than the flyer as the yarn winds on.

What are the different types of tension on a spinning wheel?

The different types of tension on a spinning wheel include Double Drive, Scotch tension, and Irish Brake.

What is the best drive band for a spinning wheel?

The best drive band for a spinning wheel is soft cotton because it allows the right amount of slippage without causing damage to the flyer or bobbin.

How does the double drive system in a spinning wheel work?

The double drive system in a spinning wheel works by using two loops of drive band, one loop adding twist to the fiber and the other controlling the winding on of the spun yarn onto the bobbin.

What factors should you consider when adjusting the tension on a spinning wheel?

When adjusting the tension on a spinning wheel, one should consider factors such as the type of fiber being used, the desired thickness of the yarn, and the speed of the wheel.

How does a flyer lead spinning wheel operate?

A flyer lead spinning wheel operates by spinning the bobbin while the flyer remains still, allowing the twist to turn the yarn before it winds onto the bobbin.