Discover the fascinating world of yarn feeders as we delve into various types and their unique functions for a seamless knitting experience.

Crocheting and knitting are not just crafts, they are art forms that require patience, skill, and the right tools. One of the most essential tools in yarn crafting is the yarn feeder.

It may seem like a small component, but it can make a significant difference in your crocheting or knitting experience. Yarn feeders come in different types and designs to suit different needs and preferences.

Whether you’re a beginner or an experienced crafter, understanding the different types of yarn feeders can help you choose the best one for your project. In this article, we’ll explore some of the most common types of yarn feeders available on the market today.

So grab your hook or needles and let’s dive into the world of yarn feeders!

Yarn Feeder Basics

Before we dive into the different types of yarn feeders, let’s start with the basics. A yarn feeder is a device that feeds yarn to your knitting or crocheting machine at a consistent rate.

It ensures that you have an uninterrupted flow of yarn while working on your project, which can save you time and frustration.

Yarn feeders come in various shapes and sizes, but they all serve the same purpose: to keep your work moving smoothly without tangling or breaking. Some are designed for specific machines or projects, while others are more versatile and can be used with different types of equipment.

When choosing a yarn feeder, it’s essential to consider factors such as compatibility with your machine type and gauge size requirements. You should also think about how much control you want over tension settings since some models offer adjustable tension options.

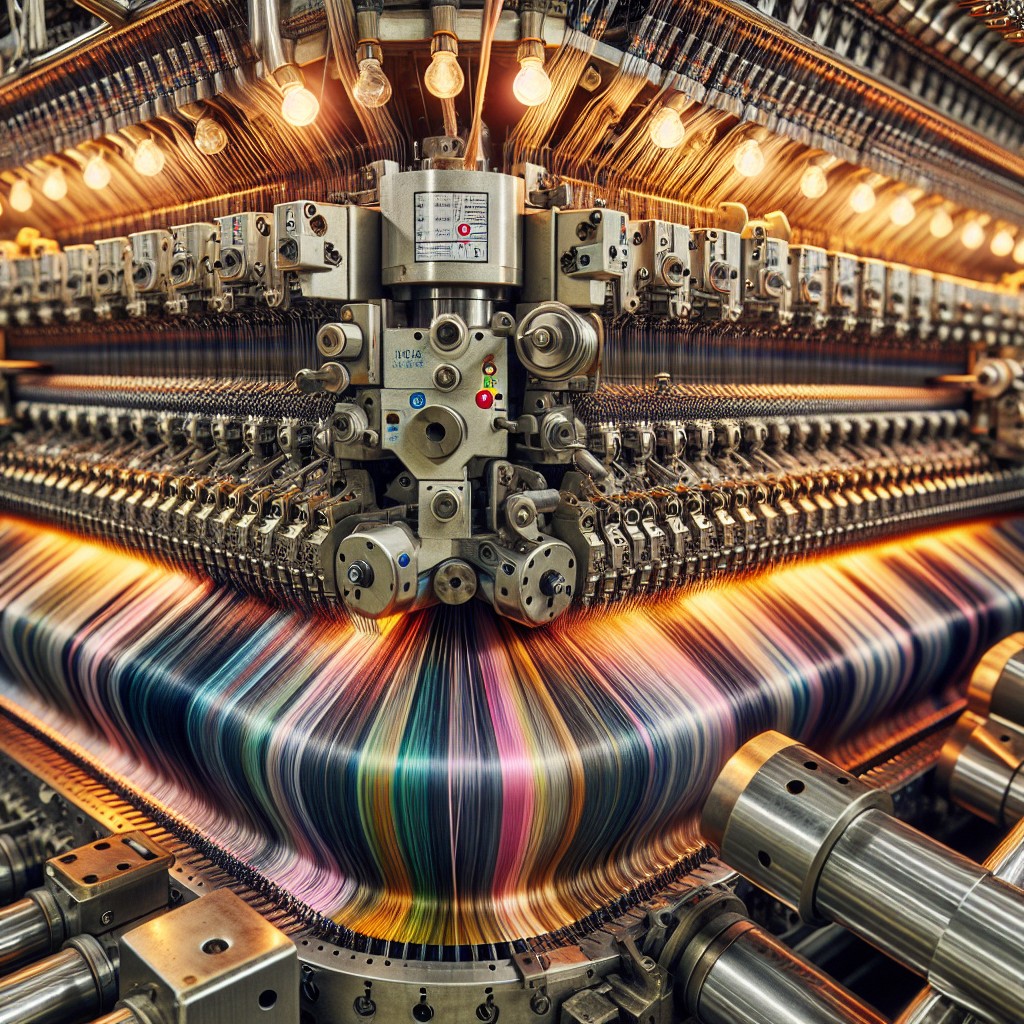

Circular Knitting Feeders

They work by feeding the yarn through a tube that rotates around the needle bed, ensuring an even and consistent flow of yarn. This type of feeder is ideal for creating seamless garments such as socks, hats, and sleeves.

One advantage of using circular knitting feeders is that they can handle multiple strands or colors at once without tangling or knotting. This makes them perfect for intricate designs with different color patterns.

There are two main types of circular knitting feeders: positive feeders and negative feeders. Positive feeders use rollers to guide the yarn onto the needles while negative feeders use suction to hold down the fabric while feeding it through.

When selecting a circular knitting feeder, consider factors such as compatibility with your machine’s gauge size and whether you need single or double feeds for your project.

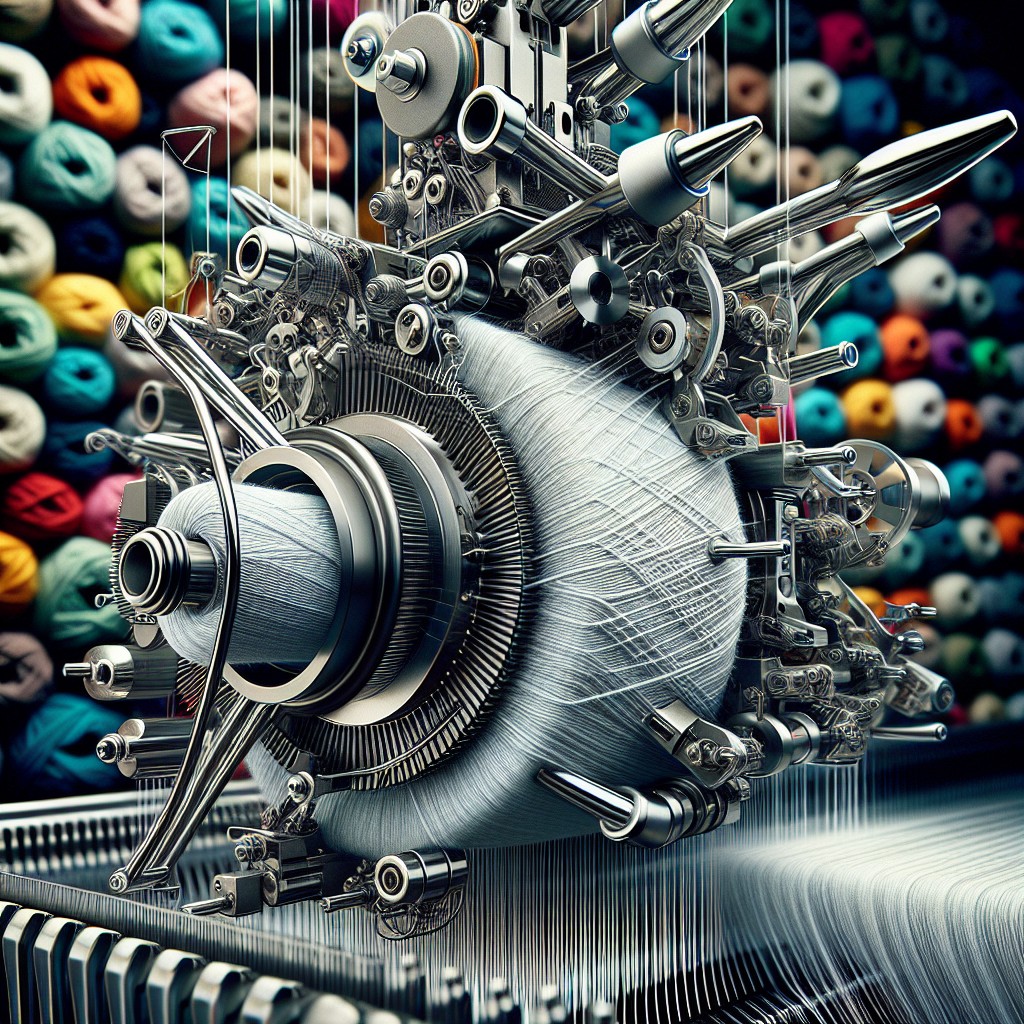

Positive Yarn Feeders

They work by using a set of rollers to feed the yarn through at a consistent rate, ensuring that there are no snags or tangles in the thread. Positive Yarn Feeders can be used with both circular and flat knitting machines, making them versatile for different types of projects.

One advantage of Positive Yarn Feeders is their ability to handle various types and thicknesses of yarn without causing any damage or breakage. This makes them ideal for working with delicate fibers such as silk or cashmere.

Another benefit is their ease-of-use; they require minimal maintenance and can be easily adjusted to suit different tension requirements depending on your project’s needs.

However, it’s important to note that positive feeders may not always provide enough tension control when working with thicker threads like wool blends. In such cases, other types like Tension Disk Feeder might come handy.

Electro-Mechanical Yarn Feeders

These feeders use an electric motor to control the yarn’s tension, ensuring that it feeds smoothly through your project. They are particularly useful when working with delicate or slippery yarns that require precise tension control.

One of the benefits of electro-mechanical yarn feeders is their ability to adjust the feeding speed according to your needs. This feature allows you to work at a comfortable pace without worrying about uneven stitches or tangled threads.

Another advantage is their compatibility with different types of knitting machines, making them versatile tools for both home-based and industrial-level projects.

However, like any other tool, electro-mechanical yarn feeders require proper maintenance and occasional repairs due to wear-and-tear over time. It’s essential always to follow manufacturer instructions on usage guidelines as well as cleaning procedures.

Tension Disk Feeders

They work by controlling the tension of the yarn as it passes through a series of disks or plates. The number and size of these disks can be adjusted to achieve different levels of tension, depending on the thickness and texture of your yarn.

One advantage to using a Tension Disk Feeder is that it allows for more precise control over your stitches, resulting in smoother and more consistent fabric. However, they do require some practice to master their use effectively.

If you’re new to using Tension Disk Feeders or any other type for that matter, take time practicing with scrap materials before starting on an actual project. This will help you get comfortable with how they work so you can avoid mistakes later on.

Tension Disk Feeders are an excellent choice if you want greater control over your stitches while working with delicate or slippery fibers like silk or rayon blends.

Pneumatic Yarn Feeders

These types of feeders use air pressure to control the flow of yarn, ensuring that it is fed smoothly and consistently through the machine. Pneumatic yarn feeders are particularly useful when working with delicate or fragile materials, as they can help prevent breakage or damage to the fibers.

One advantage of pneumatic yarn feeders is their ability to handle high-speed production without compromising on quality. They work well in industrial settings where large quantities need to be produced quickly and efficiently.

Another benefit of pneumatic yarn feeders is their versatility in handling different types of fibers, including natural and synthetic materials. This makes them an ideal choice for those who work with a variety of fabrics.

However, like any other tool or equipment used in knitting or crocheting projects, proper maintenance is crucial for optimal performance from your pneumatic feeder. Regular cleaning will ensure that there’s no buildup inside which could cause blockages leading to poor performance over time.

Double Yarn Feeders

These feeders have two separate channels that allow you to knit or crochet with both yarns simultaneously, creating unique patterns and textures in your fabric. Double Yarn Feeders can be used for various projects such as colorwork, stripes, and even cables.

One of the benefits of using a double yarn feeder is that it saves time by eliminating the need to switch between different colors or types of yarn manually. This feature makes them ideal for larger projects where changing colors frequently can become tedious.

However, it’s important to note that working with multiple strands requires more tension than usual which may cause some difficulties while knitting or crocheting if not handled properly. It’s recommended to practice first on smaller projects before moving onto bigger ones.

Accessories and Attachments

These accessories may include extra tension disks, yarn guides, or even specialized needles for certain types of projects. Some attachments can be added to a standard yarn feeder to convert it into a double-feeder or circular knitting feeder.

One popular accessory is the “yarn guide,” which helps keep your working thread in place as you knit or crochet. This attachment is especially useful when working with slippery fibers like silk or nylon.

Another essential accessory is an extra set of tension disks, which allows you to adjust the amount of tension on your yarn more precisely. Tension disk feeders are particularly helpful when using thicker threads that require more control over their flow through the machine.

When selecting accessories and attachments for your yarn feeder, consider what type of project you’ll be working on and what features will make it easier for you to achieve optimal results.

Yarn Feeder Maintenance

Proper maintenance can also help prevent issues such as yarn breakage or uneven tension. Here are some tips on how to maintain your yarn feeder:

1. Clean regularly: Dust and debris can accumulate inside the feeder, affecting its performance over time.

Use a soft brush or cloth to wipe down the exterior and interior of the feeder.

2. Lubricate moving parts: If your yarn feeder has moving parts, apply lubricant according to manufacturer instructions.

3. Check for wear and tear: Inspect all components of your yarn feeder regularly for signs of damage or wear such as cracks, chips or frayed edges.

4.Replace worn-out parts promptly: If any part is damaged beyond repair replace them immediately with genuine replacement parts from an authorized dealer.

Troubleshooting Yarn Feeder Issues

Some common problems include tangled or broken yarn, inconsistent tension, and misaligned hooks. Fortunately, most of these issues can be easily resolved with a few troubleshooting techniques.

If you’re experiencing tangled or broken yarn while using your feeder, check to make sure the path from the spool to the hook is clear and free of obstructions. You may also need to adjust your tension settings if you notice inconsistencies in your stitches.

Another issue that may arise is misaligned hooks which can cause snagging or missed stitches. In this case, carefully inspect each hook for damage and realign them as needed.

Regular maintenance such as cleaning out dust and debris from inside the feeder mechanism will help prevent many common problems before they occur.

Selecting the Right Yarn Feeder

With so many types and designs available, it’s essential to consider several factors before making a purchase. First, think about the type of project you’re working on and what kind of yarn you’ll be using.

Some feeders work better with certain types of yarn than others.

Next, consider your skill level as well as any physical limitations that may affect how you use a particular feeder. For example, some feeders require more manual dexterity than others or may be too heavy for some crafters to handle comfortably.

Another important factor is cost – while there are plenty of affordable options available on the market today, investing in a high-quality feeder can pay off in terms of durability and performance over time.

Ultimately, selecting the right yarn feeder comes down to finding one that meets your specific needs and preferences while also fitting within your budget constraints.

Innovations and Advancements

With the advent of technology, new types of yarn feeders have been developed to enhance efficiency and productivity in knitting machines. One such innovation is the electronic yarn feeder that uses sensors to detect any changes in tension or speed during knitting.

This type of feeder ensures consistent stitch quality throughout your project.

Another advancement is the use of pneumatic systems for feeding yarns into circular knitting machines. Pneumatic feeders are designed with a closed-loop system that maintains constant pressure on the thread while preventing tangling or knotting.

Moreover, some manufacturers have introduced double-yarn feeders that allow you to work with two different colors at once without having to switch threads manually constantly.

As technology continues to evolve, we can expect more innovative designs and features from future generations of yarn feeders.

From the Given Headlines

These feeders work by feeding the yarn into a circular knitting machine, which creates a continuous tube of fabric without any seams. This method is commonly used in the production of socks, hats, and other tubular garments.

Positive yarn feeders are another type that uses rollers to control the tension and speed at which the yarn feeds through to your project. They can be manually or electronically controlled depending on your preference.

Electro-mechanical Yarn Feeders use sensors to detect when there’s no more thread left on one spool before automatically switching over onto another spool so you don’t have to stop mid-project!.

Tension Disk Feeders help regulate how much tension is applied as you knit or crochet with different types and thicknesses of threads – this ensures even stitches throughout your project.

Pneumatic Yarn Feeders use air pressure instead of mechanical parts for smooth operation while Double Yarn Feeders allow two strands at once for thicker projects like blankets or scarves!.

Accessories such as attachments can also enhance functionality while proper maintenance helps prolong their lifespan. With these various options available selecting an appropriate feeder depends on factors such as budget, skill level, intended usage among others but ultimately it all boils down to personal preference!

Knitting Feeders for Fabric Perfection

They work by feeding the yarn in a circular motion, which allows for continuous and uninterrupted knitting. This type of feeder is ideal for creating garments such as socks, hats, and sweaters without any visible seams or breaks in the pattern.

Positive yarn feeders are another option that can help achieve fabric perfection. These types of feeders use rollers to control the tension on the yarn as it feeds into your project.

The result is an even distribution of tension throughout your fabric, which helps prevent uneven stitches or dropped stitches.

When selecting a knitting feeder for fabric perfection, consider factors such as ease-of-use and compatibility with your existing equipment. Some newer models offer advanced features like automatic thread cutting or adjustable stitch length settings to further enhance precision in your projects.

FAQ

What is a yarn feeder?

A yarn feeder is a device that includes a switching mechanism to preset and change the swing direction of the yarn feeding port, enabling it to move between a yarn feeding position and a standby position after completing the feeding operation.

What is full feeder and half feeder?

Full feeder refers to the use of elastene or Lycra in every feeder with yarn, while half feeder refers to its use in alternate feeders with yarn.

How many feeders are there in a knitting machine?

There are up to four (or occasionally eight) feeders in a small diameter hosiery knitting machine.

What is a positive feeder?

A positive feeder, also referred to as the MPF, is a device that consistently feeds yarn to a knitting machine at a specific speed using loops in order to maintain even knitting.

What is a yarn feeder?

A yarn feeder is a device used in knitting machines to guide and control the tension of yarn during the knitting process.

A yarn feeder is a device used in knitting machines to supply yarn to the needles during the knitting process. It ensures consistent tension and smooth delivery of yarn, allowing for even stitches and better overall fabric quality

A yarn feeder is a knitting machine component that supplies yarn to the needles, ensuring consistent tension and smooth delivery for even stitches and improved fabric quality.

Please provide the specific question or the snippet you’d like me to consider for formulating an answer in a natural language processing-friendly format.

What is full feeder and half feeder?

Full feeder and half feeder are terms used in the printing industry, where a full feeder refers to a printing press that feeds full-sized sheets of paper, while a half feeder refers to one that handles smaller, half-sized sheets of paper.

Full feeder and half feeder are types of yarn feeding systems used in circular knitting machines. A full feeder provides yarn to every needle in the cylinder, allowing for simultaneous knitting of all stitches in a single course. A half feeder supplies yarn to only half of the needles at a time, requiring two courses to complete one full round of knitting. Full feeders are typically used for quicker production and large-scale knitting, while half feeders may be used for more intricate patterns and details

In circular knitting machines, full feeders provide yarn to every needle for simultaneous knitting and quicker production, while half feeders supply yarn to half the needles at a time for more intricate patterns and details.

Please provide the snippet and the question you want answered in one sentence using an NLP-friendly format.

How many feeders are there in a knitting machine?

In a knitting machine, there are typically two feeders.

The number of feeders in a knitting machine can vary depending on the machine type, its configuration, and the required applications. Machines typically range from having one feeder for single-color knitting to multiple feeders for multi-color or complex pattern designs

The number of feeders in a knitting machine varies based on machine type, configuration, and required applications, ranging from one feeder for single-color knitting to multiple feeders for multi-color or complex pattern designs.

Please provide the snippet and the question for me to generate a response.

What is a positive feeder?

A positive feeder is an individual or action that promotes and supports the growth and success of others through encouragement and constructive feedback.

A positive feeder is a yarn feeding mechanism that actively controls the tension and feed rate of the yarn supplied to the knitting machine. This type of feeder uses rollers, movable yarn guides, or a combination of both to ensure the yarn is provided at the precise tension and timing required by the knitting process. Positive feeders allow for improved fabric quality, reduced yarn waste, and increased knitting efficiency

A positive feeder is a yarn feeding mechanism that actively controls tension and feed rate using rollers and movable yarn guides, resulting in improved fabric quality, reduced yarn waste, and increased knitting efficiency.

Please provide the question and the snippet for me to generate an appropriate answer.

Suggested Additional Questions

Snippet: "Smart devices make daily tasks easier and more efficient." Question: What impact do smart devices have on daily tasks? Answer: Smart devices make daily tasks easier and more efficient.

How do yarn feeders contribute to producing different stitch patterns in knitting?

Yarn feeders contribute to producing different stitch patterns in knitting by controlling and managing the flow of yarn, enabling the creation of diverse textures and designs.

What factors affect the performance and efficiency of yarn feeders in knitting machines?

Answer: Factors affecting yarn feeder performance and efficiency in knitting machines include yarn tension, yarn path, yarn guide design, yarn material properties, and mechanical and electrical characteristics of the feeder system.

What are some common maintenance concerns or required adjustments for yarn feeders in knitting machines?

Some common maintenance concerns or required adjustments for yarn feeders in knitting machines include cleaning, lubrication, tension adjustments, and replacement of worn parts.