Discover the diverse world of yarn numbering systems as we unravel various methods used to determine the thickness and weight of your favorite fibers.

Have you ever walked into a yarn store and felt overwhelmed by the variety of yarns available? With so many different types of fibers, colors, and textures to choose from, it’s easy to get lost in the sea of options. But have you ever stopped to consider the numbering system that appears on each skein or ball of yarn? Understanding this system can help you make informed decisions about which yarn is best suited for your project.

In this article, we’ll explore the types of yarn numbering systems used in the industry and how they can guide your crochet or knitting journey. So grab a cup of tea and let’s dive into the world of yarn!

Yarn Numbering Systems

Yarn numbering systems are used to determine the thickness and weight of yarn. These systems help manufacturers, designers, and crafters communicate about the properties of a particular yarn.

There are two main types of yarn numbering systems: direct and indirect.

Direct Systems involve measuring the length or weight of a fixed amount (usually one gram) of thread or fiber. The higher the number assigned to this measurement, the thinner or finer is considered that thread/fiber.

Indirect Systems measure how many threads can fit into a specific area (usually one inch). In this case, lower numbers indicate thicker fibers while higher numbers represent thinner ones.

Direct Systems

In this system, the higher the number, the thicker and heavier the yarn. This means that a 4-ply or fingering weight yarn will have a lower number than a bulky or super bulky weight yarn.

One example of direct counting is “denier,” which measures mass in grams per 9,000 meters (or approximately 5.6 miles) of fiber length. Another example is “tex,” which measures mass in grams per kilometer (or approximately .62 miles) of fiber length.

Direct systems are easy to understand and use because they directly indicate how thick or thin a particular type of thread is without requiring any conversion calculations.

Indirect Systems

Unlike direct systems, which measure the weight or thickness of a single strand of yarn, indirect systems take into account multiple strands twisted together to form a plied yarn.

One example of an indirect system is the cotton count system (Ne), which measures how many hanks (840 yards) weigh one pound. For instance, if 1 pound contains 20 hanks, then it would be labeled as Ne20.

Another common indirect system is the metric count system (Nm), which measures how many meters weigh one gram. So if you have a skein labeled Nm10/2, this means that there are two strands twisted together and each strand has a length of 10 meters per gram.

Understanding these different types of numbering systems can help you choose the right type and weight for your project needs.

Conversion of Yarn Count Units

These units can be confusing and make it difficult for crafters to choose the right yarn for their project. However, understanding how these different units relate to each other can help you navigate through this maze.

The conversion of yarn count units is a crucial aspect that every crafter should know when working with different types of fibers. It involves converting one unit into another so that you can compare threads or determine which thread will work best for your pattern.

For instance, if a pattern calls for 4-ply worsted weight wool but all you have is DK weight cotton, then knowing how to convert between these two types of threads will save your project from disaster!.

Comparing Threads for Changing Patterns

Whether you’re substituting a discontinued brand or simply looking for an alternative fiber, comparing threads can be tricky. However, understanding the different numbering systems can help simplify this process.

For example, if your pattern calls for a specific weight of yarn and you want to substitute with another type of thread that has different numbering system units (such as Tex or Denier), you’ll need to convert the count units first before making any decisions. This will ensure that your new thread matches up with the original in terms of thickness and weight.

Another important factor when comparing threads is measuring their ratio of thicknesses. This involves calculating how many strands are needed from one type of yarn to match another’s gauge swatch accurately.

Measuring the Ratio of Thicknesses

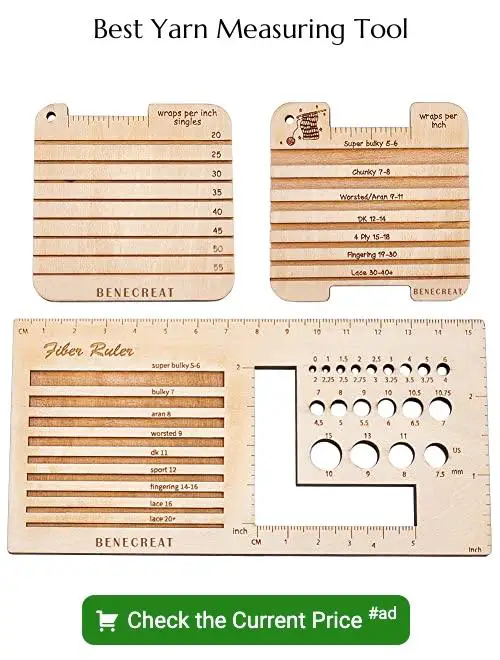

Measuring the ratio between different yarns can help you determine how many strands you need to achieve your desired thickness. To measure this ratio, take two pieces of thread and wrap them around each other until they form a single strand.

Then count the number of wraps per inch (WPI) for each individual thread and divide one by another to get their WPI ratio.

For example, if one strand has 10 WPI and another has 5 WPI, their ratio would be 2:1 (10 divided by 5). This means that you’ll need two strands from the thinner yarn for every one strand from the thicker yarn.

Equivalent Size

It’s essential when you want to substitute one type of thread for another in a pattern. For example, if your pattern calls for worsted weight yarn, but you only have sport weight on hand, knowing the equivalent size can help ensure that your finished project turns out as intended.

To determine the equivalent size between two different types of threads or fibers, it’s important first to understand their respective numbering systems and how they relate. Once you know this information, there are several online calculators available that can help make conversions easier.

Keep in mind that while two threads may have similar numbers assigned by their respective systems doesn’t necessarily mean they will be identical in thickness or texture.

Common Numbering Systems

The Tex system is widely used in Europe and measures the weight of a kilometer of yarn. On the other hand, Denier is commonly used to measure synthetic fibers such as nylon or polyester and refers to how many grams 9 kilometers (10k yards) weigh.

Cotton count system is another popular method that originated from England during industrialization when cotton was a primary fiber for textiles production. It counts how many hanks (840 yards each) make up one pound of cotton thread.

Yarn Count Conversion Calculator

But what happens when you come across a pattern that calls for a specific yarn weight or count that’s not in your collection? This is where the Yarn Count Conversion Calculator comes in handy. With this tool, you can easily convert between different numbering systems to find the equivalent size of your desired yarn.

Whether it’s converting from Tex to Denier or Cotton Count to Metric Count, this calculator takes the guesswork out of finding the right thread for your project. Simply input the values into each field and let it do its magic! It’s an essential tool for any crafter who wants to expand their horizons beyond their current stash.

Understanding different types of yarn numbering systems is crucial if we want our projects to turn out as intended.

Tex System

This method is commonly used in Europe and Canada, but it’s not as popular in the United States. The Tex number indicates how many grams one kilometer of yarn weighs, so a higher Tex number means thicker and heavier yarn.

For example, if you have 1000 meters (or 1 kilometer) of cotton thread that weighs 25 grams, then its Tex size would be calculated as follows:.

Tex = Weight (in grams) / Length (in meters) Tex = 25 / 1000 Tex = 0.025.

Therefore this cotton thread has a tex size of “twenty-five”.

Understanding different types of numbering systems can help you choose the right type and thickness for your project needs.

Ticket Number

It measures the weight of a yarn by counting how many hanks (a length of 560 yards) weigh one pound. The higher the ticket number, the finer and lighter weight the yarn will be.

For example, if a pound of cotton fiber produces 840 yards long thread or two hanks, then it would have been assigned ticket number 2/40s (pronounced “two-forties”). This means that there are two strands with each strand having forty hanks per pound.

The Ticket Number system can be confusing for beginners as it uses fractions to indicate thickness rather than direct measurements like other systems. However, once you understand how this numbering system works, you’ll find it easier to compare different types of fibers and choose which ones work best for your project.

Cotton Count System

It originated in England and was widely adopted by the textile industry worldwide. The system measures the number of hanks (840 yards) per pound of yarn, with higher numbers indicating thinner threads.

For example, a 20-count cotton thread means that there are 20 hanks (or 16,800 yards) in one pound of yarn. On the other hand, a thicker thread like an eight-count would have only eight hanks or 6,720 yards per pound.

This system is particularly useful for crocheters and knitters who work with cotton fibers as it allows them to choose appropriate weights for their projects based on their desired outcome. A finer weight will produce more delicate results while thicker weights will create bulkier textures.

The Hong Kong Ticket System

This system uses a ticket number to indicate the weight of the yarn, with lower numbers indicating thicker yarns. For example, a 1/0 ticket represents very thick yarn while an 18/0 ticket represents very thin thread.

While this system may seem confusing at first glance, it can be useful for those who are familiar with it. If you’re used to working with this type of numbering system or if you’re purchasing Asian-made products, then understanding how the Hong Kong Ticket System works can help ensure that you get exactly what you need for your project.

However, if you’re new to crocheting or knitting and have never encountered this type of numbering before, don’t worry! There are many other types of systems out there that use more straightforward methods for determining thickness and weight. It’s always best to do some research beforehand so that you know which method will work best for your needs.

Denier System

This method is commonly used for synthetic fibers such as nylon and polyester. The higher the denier number, the thicker and heavier the yarn will be.

For example, a 100-denier thread would weigh 100 grams per every 9 kilometers (or approximately six miles) of length. This measurement can help you determine which type of thread to use for your project based on its intended purpose.

If you’re looking to create durable outdoor gear or heavy-duty bags, using a high-denier thread may be ideal due to its strength and thickness. On the other hand, if you’re working on delicate lacework or lightweight garments like summer tops or shawls then choosing lower deniers might work better.

Metric Count System

This system is commonly used in Europe and other parts of the world, but it’s not as popular in North America. The metric count number indicates how many kilometers of yarn can be spun from one kilogram of fiber.

For example, if a particular type of yarn has a metric count number of 10,000 meters per kilogram (m/kg), then 10 kilometers (or 10,000 meters) can be spun from one kilogram.

While this may seem like an overly complicated way to measure yarn thickness and weight compared to other systems such as the direct or indirect systems we’ve discussed earlier; it does have its advantages for manufacturers who need precise measurements for their products.

Understanding different types of numbering systems will help you choose your preferred method when working on your next project or purchasing new materials at your local craft store. Whether you prefer using traditional methods or modern technology tools like conversion calculators – knowing what each system means will make all the difference!

FAQ

How many types of yarn numbering systems are there?

There are two types of yarn numbering systems: Direct system and Indirect system.

What are the different types of yarn classification?

Answer: The different types of yarn classification are staple fiber yarn, ply yarns, and filament yarn.

What is the yarn numbering system?

The yarn numbering system is a method to denote the yarn’s linear density as a weight-to-length ratio, commonly used for synthetic or man-made fibers, such as denier, which expresses the weight in grams per 9000 meters.

What are the factors that affect yarn numbering systems?

Yarn numbering systems are affected by factors such as the fiber length, weight, and yarn density.

How does the yarn numbering system influence the quality and characteristics of yarn?

The yarn numbering system influences the quality and characteristics of yarn by determining its fineness, with higher numbers representing finer yarns which leads to smoother and lighter fabrics.

How do different yarn numbering systems affect textile manufacturing?

Different yarn numbering systems affect textile manufacturing by determining yarn thickness, which influences fabric properties and processing requirements.