Explore the functionality and convenience of a skirting table for fiber crafts because its design enhances the preparation phase of your crocheting and knitting projects.

Key takeaways:

- PVC pipes and connectors are needed for the frame.

- Choose a sturdy mesh or wire grid for the table top.

- Use PVC cement and pipe cutters for assembly.

- Customize the size of the table to fit your needs.

- Skirting tables are used to prepare and inspect fiber projects.

Materials Needed for a PVC Skirting Table

For the creation of a PVC skirting table, you’ll require various materials that are both durable and easy to work with. Collect PVC pipes, typically 1 1/2-inch in diameter, for the frame. Their lightweight nature makes them ideal for constructing a portable table. You’ll also need PVC connectors such as elbow joints, T-joints, and four-way fittings to piece the frame together efficiently.

Select a mesh or wire grid for the table top, which allows dirt and small debris from raw fleece to fall through while cleaning. Ensure the mesh is sturdy enough to hold the fleece but with openings large enough for debris to pass through.

You’ll require PVC cement or appropriate adhesives for securing joints, though some may choose slip-fit joints for easy disassembly. Additionally, gather pipe cutters for precision cutting of pipes to the desired lengths, and caps to cover the pipe ends, for safety and a clean finish.

Consider the overall dimensions of your table while selecting your materials, accounting for a comfortable working height and adequate surface area to suit your skirting needs. Remember, the size can be customized based on your personal requirements and the space available in your crafting area.

Tools Required for Assembly

Before starting the assembly of your PVC skirting table, gather the following tools to ensure a smooth construction process:

- Tape Measure: Precisely measure each PVC pipe to match the dimensions of your design.

- PVC Cutter or Hacksaw: Use this to cut the PVC pipes to the required lengths accurately.

- Sandpaper: Smooth the cut edges of the PVC pipes to prevent any snagging on fibers or potential injury.

- PVC Primer and Cement: Apply these to securely join the PVC pipes and fittings.

- Mallet or Rubber Hammer: Gently tap the PVC fittings into place without damaging them.

- Adjustable Wrench: Tighten any bolts or screws if your design includes metal clamps or hinges.

- Level: Ensure all components of the table are perfectly horizontal for stability during use.

Having these tools readily available will streamline the construction process, allowing for an efficient build.

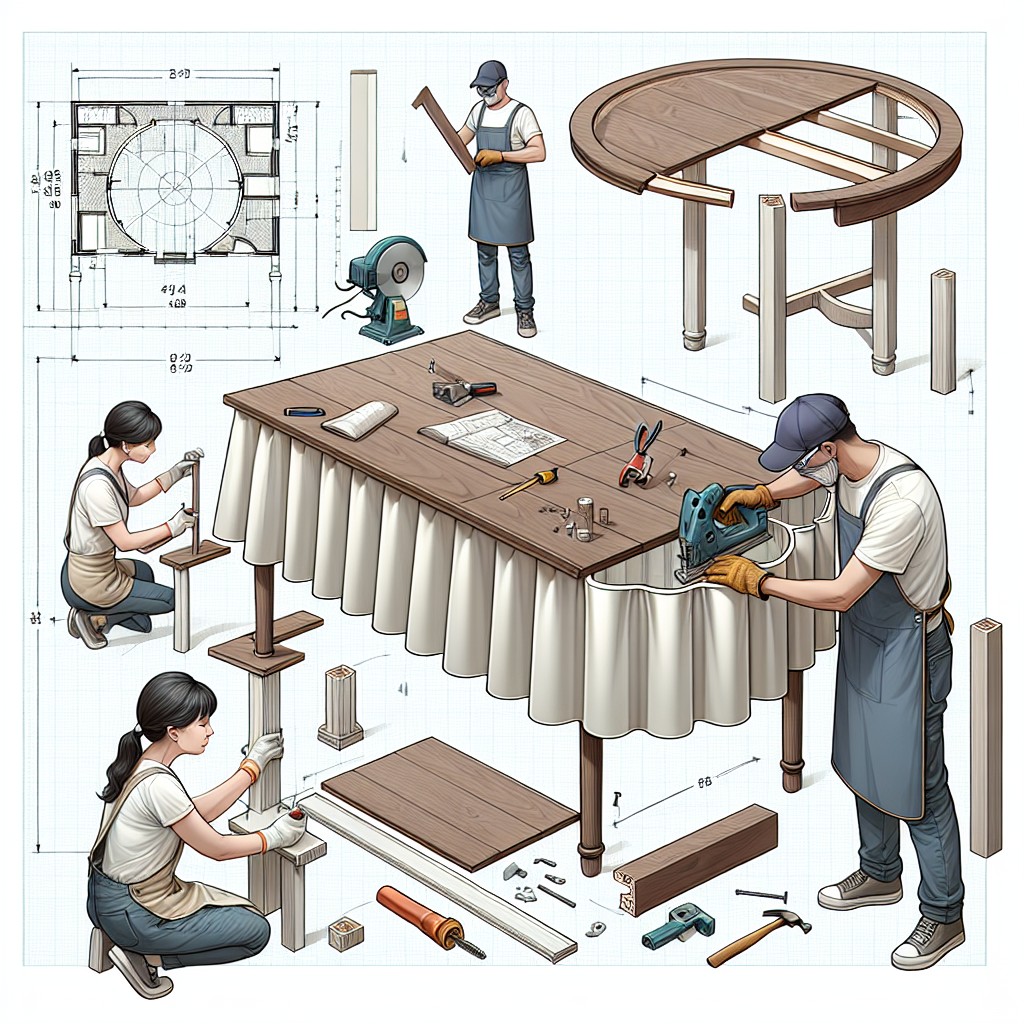

Step-by-Step Construction of a PVC Skirting Table

Begin with cutting the PVC pipes to the required lengths for legs, supports, and the frame of your table, following the dimensions of your design plan.

Connect the leg pieces using T-joints to create a stable base. Ensure all connections are secure and that the legs are of equal length for the table to stand level.

Attach horizontal support pipes between the legs using cross or T-joints to create added stability and a frame to support the tabletop grid.

Assemble the tabletop grid from smaller PVC pipe sections and connect them using four-way joints to create a sturdy surface that allows debris and dirt to fall through while cleaning fleece.

Lay the cut wire mesh over the tabletop frame and secure it with zip ties or PVC cement, trimming any excess to prevent sharp edges that could snag yarn or wool.

Cap all external PVC ends with end caps for a finished look and to ensure a smooth surface.

Test the stability and adjust any loose fittings before use. Reinforce joints with PVC cement if necessary for a more permanent structure.

With these steps, you have a functional skirting table ready for fiber processing tasks.

Utilizing the Skirting Table for Fiber Projects

A skirting table is a dedicated space for inspecting and preparing your fiber before spinning or felting. Place raw fleece atop the mesh surface to remove debris, second cuts, and undesirable parts of the fleece, allowing unwanted materials to fall through the mesh. This preparation improves the quality of the final spun yarn.

When skirting on the table, spread the fleece evenly to assess its quality and consistency. Identify parts with excessive vegetable matter or undesired attributes, and discard them. The process is crucial for crafting high-quality fiber products such as yarn, rovings, and batts.

After skirting, you may wash the fleece directly on the table. The mesh design facilitates water drainage and eliminates the need for additional handling, which can felt or damage fibers.

The table also serves as an excellent surface for drying cleaned fibers, ensuring good air circulation around the fleece for quicker and more even drying.

In felting projects, the table provides a flat, stable area to lay out fibers. It offers an ideal platform for needle felting, allowing the felting needles to go through the fibers without resistance, which protects your working surface from damage.

Maintenance and Care of Your Skirting Table

To ensure the longevity and functionality of your skirting table, regular maintenance is key. Start by wiping down the surface after each use to remove dirt and grime, which can be easily done with a damp cloth.

For wooden tables, it’s pivotal to check for signs of splintering or cracking, which can be addressed by sanding and applying linseed oil to protect the wood.

Periodically check all connections and hardware for tightness, as loose screws or joints can compromise the table’s stability.

For PVC constructions, inspect the joins to ensure they are sealed well, applying PVC cement if any have come loose over time.

Avoid prolonged exposure to direct sunlight and extreme weather, as this can warp or degrade materials.

If your skirting table is collapsible, make sure all moving parts are lubricated to prevent rust or difficult folding.

Proactive measures such as covering the table when not in use can prevent unexpected damage and prolong the usefulness of the table.

Take time for these simple care practices, and your skirting table will remain a durable, reliable asset for your fiber projects.

Safety Precautions While Using Skirting Tables

When utilizing a skirting table, it’s crucial to prioritize safety to prevent accidents and injuries. Here are practical tips to ensure a secure experience:

- Ensure Stability: Before placing any fiber on the table, verify that the legs are locked in place and the surface is level to prevent tipping.

- Keep Sharp Tools in Check: If using shears or other sharp instruments, keep them in a safe area when not in use and handle them with care, especially when reaching across the table.

- Manage Cords: If your skirting table has any attached lighting or tools, keep cords tidy and out of walkways to avoid tripping hazards.

- Wear Appropriate Gear: Protective gloves can shield your hands from rough fibers and prevent cuts, while anti-slip footwear can prevent slips and falls around the skirting area.

- Be Aware of Ergonomics: Adjust the height of the table if possible to maintain good posture while working, reducing the risk of back strain.

- Clear Work Area: Regularly remove debris and loose materials from the work surface to maintain a clear area, minimizing the risk of accidents.

- Stay Focused: Always pay attention to your task at hand. Distractions can lead to mishandled tools or improper handling of fibers, which could result in injury.

- Keep Emergency Supplies at Hand: Have a first aid kit nearby along with emergency contact numbers in case any accidents occur.

By adhering to these safety guidelines, you’ll create a more enjoyable and incident-free environment for your yarn crafting sessions.

Transport and Storage Solutions for Collapsible Skirting Tables

Collapsible skirting tables are a convenient option for crafters who require mobility or have limited space. To ensure ease of transport, many models are designed to fold into a compact form. When folded, they can fit in the backseat of a car or a large trunk. Some have carry handles or straps for ease of lifting.

For storage, these tables can be slipped into a closet, slid under a bed, or placed against a wall in a craft room. If a storage bag is not included with your table, consider using a canvas bag or a custom-sewn cover to protect it from dust and damage. To maximize space, store related crafting tools and accessories within the table’s underside while it is folded. Always secure any loose parts or accessories to prevent them from getting misplaced or causing injury during transportation.

Troubleshooting Common Issues With Skirting Tables

Occasionally, a skirting table may encounter issues that impact its performance and usability. Addressing these effectively ensures the longevity of your table and the quality of your fiber work.

Wobbling: If the table wobbles, check the joints for tightness. Over time, fittings may loosen, so simply tightening them can stabilize the structure. Ensure the floor is even where you set up the table.

Netting Sag: Weight from the fleece can cause the netting to sag. If this happens, verify that the net is properly secured at all attachment points. Using a smaller mesh or incorporating additional support beams beneath can provide extra strength.

Difficulty Cleaning: Fleece debris stuck in the netting requires removal. Use a soft brush to gently clean the mesh without damaging it. For persistent debris, detach the netting for a more thorough wash.

Connectivity Issues: For tables with collapsible features, correct reassembly is key. If sections aren’t aligning, consult the instruction manual to ensure each part is oriented correctly.

By swiftly addressing these common concerns, your skirting table will remain a reliable aid in your fiber crafting processes.

Recommended Accessories for Skirting Table Efficiency

Mesh bags or laundry sacks can be clipped onto the sides of your skirting table to hold discarded fiber, allowing for easy sorting and disposal. Fleece-lined work gloves improve grip and protect hands from long periods of handling wool. Additionally, installing small bins or containers on the table legs ensures that tools like scissors, markers, and tags are within easy reach. Portable scales can be used to weigh the fleece after skirting, providing immediate feedback on yield. For those who skirt wool frequently, consider a swivel stool to maintain comfort during longer sessions. A magnifying glass with a clamp or stand might be handy for examining the fleece more closely for impurities or assessing the quality of the fibers.

Exploring Different Styles of Skirting Tables

When delving into the variety of skirting tables available, consider their structural designs and functional features. Traditional wood tables offer stability and a classic feel, but they may be heavier and less portable. PVC tables, on the other hand, are lightweight, affordable, and easy to assemble.

Adjustability is another factor, with some tables featuring legs that can be set to different heights to suit the user’s comfort. For small-scale use or travel, collapsible skirting tables are ideal, folding down for convenience and space-saving. The market also provides options with built-in storage, such as shelves or pockets, to keep tools and accessories within reach.

Certain skirting tables are designed with a grid or mesh surface to allow debris to fall through, thus keeping the fleece cleaner. When working with finer fibers, a skirting table with a solid worktop or smaller gauge mesh prevents small pieces from being wasted.

Ultimately, the choice hinges on specific needs, whether it’s maximized portability for those who attend fiber fairs or ergonomics for the comfort of home use. Consider the volume of fiber to be skirted, storage space available, and personal workflow to make an informed decision.

FAQ

What is skirting on a table?

Skirting on a table refers to a specific kind of tablecloth designed to conceal the table legs, primarily utilized during food service in dining areas, restaurants, banquet halls, or event venues.

How important is table skirting?

Table skirting is critical as it enhances the aesthetic appeal of the display by concealing unattractive table legs, thereby augmenting the allure of the tabletop décor.

What is the best fabric for table skirting?

The best fabric for table skirting is polyester due to its resistance to staining, spills, and creases, along with its machine-washable nature, making it ideal for venues with frequent events.

What are the different styles of table skirting and how do they affect the aesthetic appeal?

The different styles of table skirting involve box pleat, shirred, accordion pleat, and fringe, each adding to the aesthetic appeal by providing various dimensions, textures, and lines to the table design.

How to properly care for and clean table skirting to maintain its quality?

To maintain the quality of table skirting, it should be gently washed in warm water, using mild detergent, and air-dried, avoiding direct sunlight and harsh chemicals.

Can you DIY table skirting and what materials will you need?

Yes, you can DIY table skirting using materials such as fabric or yarn, a measuring tape, scissors, a sewing machine or crochet hook, and a tablecloth or clips to secure the skirt to the table.