Discover the variety of yarn tensioners available in the market, as we delve into their unique features and benefits to enhance your knitting and crocheting experience.

Are you tired of your yarn getting tangled up and causing frustration during your crochet or knitting projects? Then you might want to consider using a yarn tensioner. These handy tools help regulate the tension of your yarn, making it easier to work with and ensuring that your stitches are consistent.

But with so many different types of yarn tensioners on the market, how do you know which one is right for you? In this article, we’ll explore some of the most popular types of yarn tensioners and their unique features. So whether you’re a seasoned crafter or just starting out, read on to find out which type of yarn tensioner will best suit your needs!

Spring Tensioners

They work by using a spring to regulate the amount of tension on your yarn, making it easier to work with and ensuring that your stitches are consistent. Spring tensioners come in different shapes and sizes, but they all function similarly.

One advantage of spring tensioners is their ease-of-use. They can be easily attached to any surface or table edge, allowing you to adjust them according to your preference while working on a project.

Another benefit is their affordability; they’re relatively inexpensive compared with other types of yarn tensioning devices like hysteresis or gate/storage systems.

However, there’s also a downside: some crafters find that spring-based systems may not provide enough control over finer threads such as silk or lace-weight wool because these materials require more delicate handling than thicker fibers like cotton or acrylics which tend not stretch as much under pressure from springs.

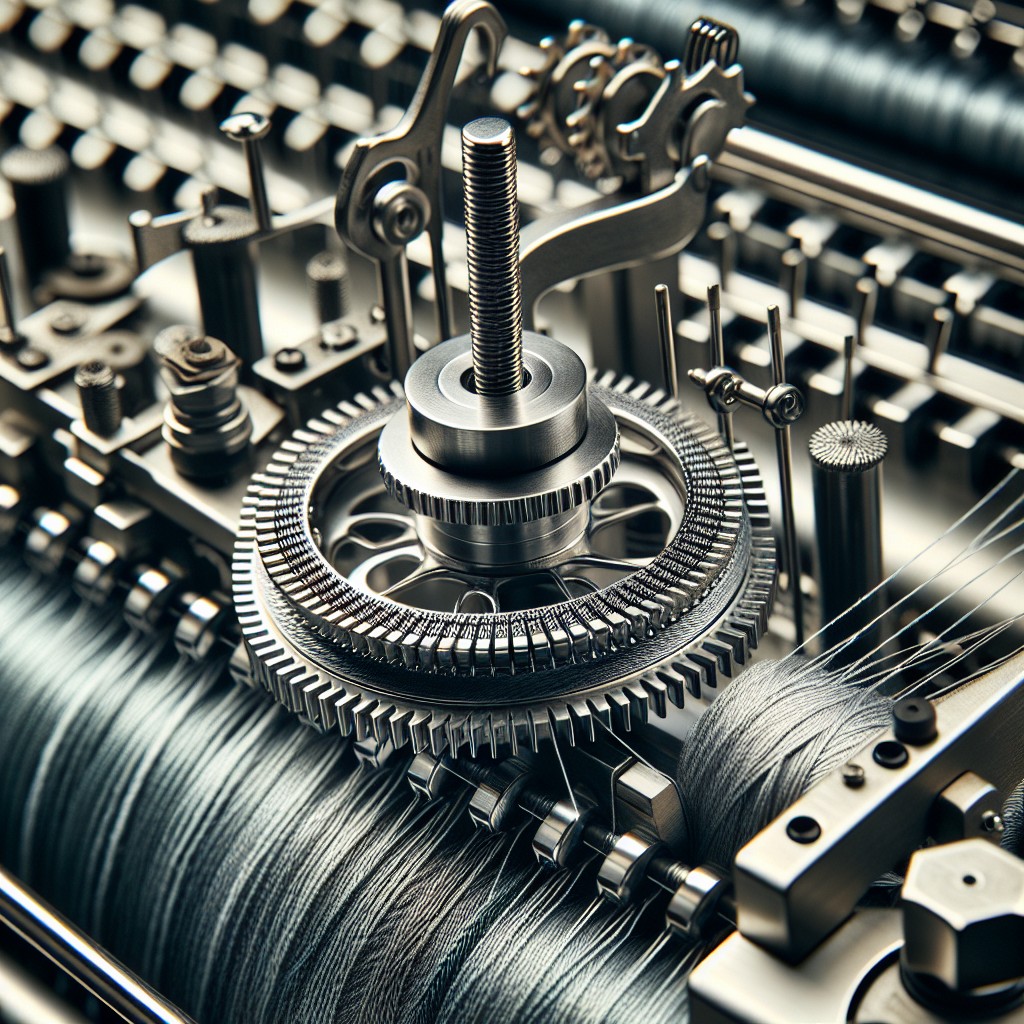

Washer Tensioners

They consist of a small metal or plastic washer with a hole in the center, through which you thread your yarn. The washer is then attached to your knitting or crochet project using either clips or hooks.

One advantage of using washer tensioners is that they allow for gradual application of tension, which can be especially helpful when working with delicate fibers like silk or cashmere. Because they are so simple and lightweight, they don’t add any extra weight to your project.

However, one potential downside to using washer tensioners is that they may not provide enough resistance for thicker yarns or heavier projects. In these cases, you may need to opt for a more heavy-duty type of yarn tensioner.

Gate and Storage Tensioners

These tensioners work by holding the yarn in place with a gate or clamp, which can be adjusted to regulate the amount of tension on the yarn. Gate and storage tensioners are particularly useful for larger projects where you need to store your work between sessions.

One advantage of using gate and storage tensioners is that they allow you to easily adjust the amount of slack in your yarn without having to reposition it every time. This makes them ideal for working on complex patterns or designs where precise tensions are required.

Another benefit is their portability; many models come with built-in clamps or hooks, making them easy to attach onto tables, chairs, or other surfaces while working on-the-go.

Hysteresis Tensioners

These devices work by using two magnets, one stationary and one movable, which create a magnetic field that pulls on the yarn passing through it. The movable magnet is attached to a spring or other mechanism that allows you to adjust the amount of tension applied.

One advantage of hysteresis tensioners is their ability to maintain consistent levels of resistance even as temperature and humidity conditions change. This makes them ideal for use in environments where these factors can fluctuate significantly.

Another benefit is their ease-of-use; they require minimal setup time and can be adjusted quickly with just a few simple movements.

Yarn Tension in Knitting

When you knit with too much tension, your stitches will be tight and compact, resulting in a stiff fabric that doesn’t drape well. On the other hand, if you knit with too little tension, your stitches will be loose and unevenly spaced out.

To achieve optimal yarn tension in knitting requires practice and patience. It’s essential to find the right balance between holding onto the yarn tightly enough to create even stitches while still allowing it to flow smoothly through your fingers.

One way to improve yarn tension when knitting is by using a proper technique for holding both needles simultaneously while maintaining consistent pressure on each stitch as you work across them row by row.

Measuring Yarn Tension

But how do you know what that correct amount is? Measuring your yarn tension can help ensure that you’re getting consistent results with each stitch.

There are several ways to measure yarn tension, including using a gauge swatch or a specialized tool called a “tension meter.” A gauge swatch involves knitting or crocheting a small sample piece and measuring it to determine if it matches the pattern’s recommended gauge. This method can be time-consuming but provides accurate results.

A more efficient way to measure your yarn’s tension is by using an electronic or mechanical device called a “tension meter.” These devices work by clamping onto your working thread and measuring its resistance as it passes through. The resulting measurement gives you an accurate reading of how much force is required to pull the thread through at any given point in time.

Yarn Tension During Winding

Yarn tension during winding can be controlled using a variety of methods, including manual control or automatic systems. Manual control involves adjusting the speed at which you wind the yarn by hand, while automatic systems use sensors and motors to regulate tension automatically.

One popular type of automatic system is a motorized winder with built-in tension controls. These machines are designed specifically for winding large quantities of yarn quickly and efficiently while maintaining consistent tension throughout the process.

Another option for controlling yarn tension during winding is using a swift and ball winder combination tool. This allows you to easily wind your skeins into neat balls without having them tangle up or lose their shape due to uneven tensions.

Gradual Application of Tension

This means that the tension should be applied slowly and steadily, rather than all at once. Gradual application of tension helps prevent your yarn from breaking or becoming too tight, which can cause uneven stitches and frustration during your project.

One way to achieve gradual application of tension is by using a spring-loaded yarn tensioner. These types of tensioners allow you to adjust the amount of pressure on your yarn with a simple turn of a dial or knob.

As you work with the yarn, the spring will gradually apply more or less pressure as needed.

Another option for achieving gradual application of tension is by using weights on your skein or ball while working with it. By attaching small weights (such as washers) to either end of your skein/ball before starting work, you can create an even distribution in weight throughout the length being worked upon; this ensures that there are no sudden changes in resistance when pulling out new lengths from within its folds.

Yarn Preparation for Weaving: Warping

It involves measuring and winding the yarn onto a warping board or reel to create a warp, which is then transferred to the loom. During this process, it’s important to maintain consistent tension on the yarn so that it doesn’t become tangled or stretched out of shape.

Yarn tensioners can be particularly helpful during warping as they help regulate the amount of tension applied to each strand of yarn. This ensures that all strands are evenly spaced and under equal pressure, resulting in a more uniform finished product.

There are several types of tensioners available for use during warping including spring-loaded devices and gate-style systems. The choice will depend on personal preference as well as factors such as budget and project requirements.

Tsudakoma New Tensioner Device

This innovative device uses advanced technology to provide precise and consistent tension control for all types of yarns. The Tsudakoma tensioner is designed to be easy to use and can be adjusted quickly and easily depending on your specific needs.

One of the key benefits of this new device is its ability to maintain constant tension even when working with different types or thicknesses of yarn. This means that you can switch between projects without having to worry about adjusting your tension settings each time.

The Tsudakoma tensioner also features an intuitive interface that allows you to monitor your thread tensions in real-time, giving you greater control over the quality and consistency of your stitches.

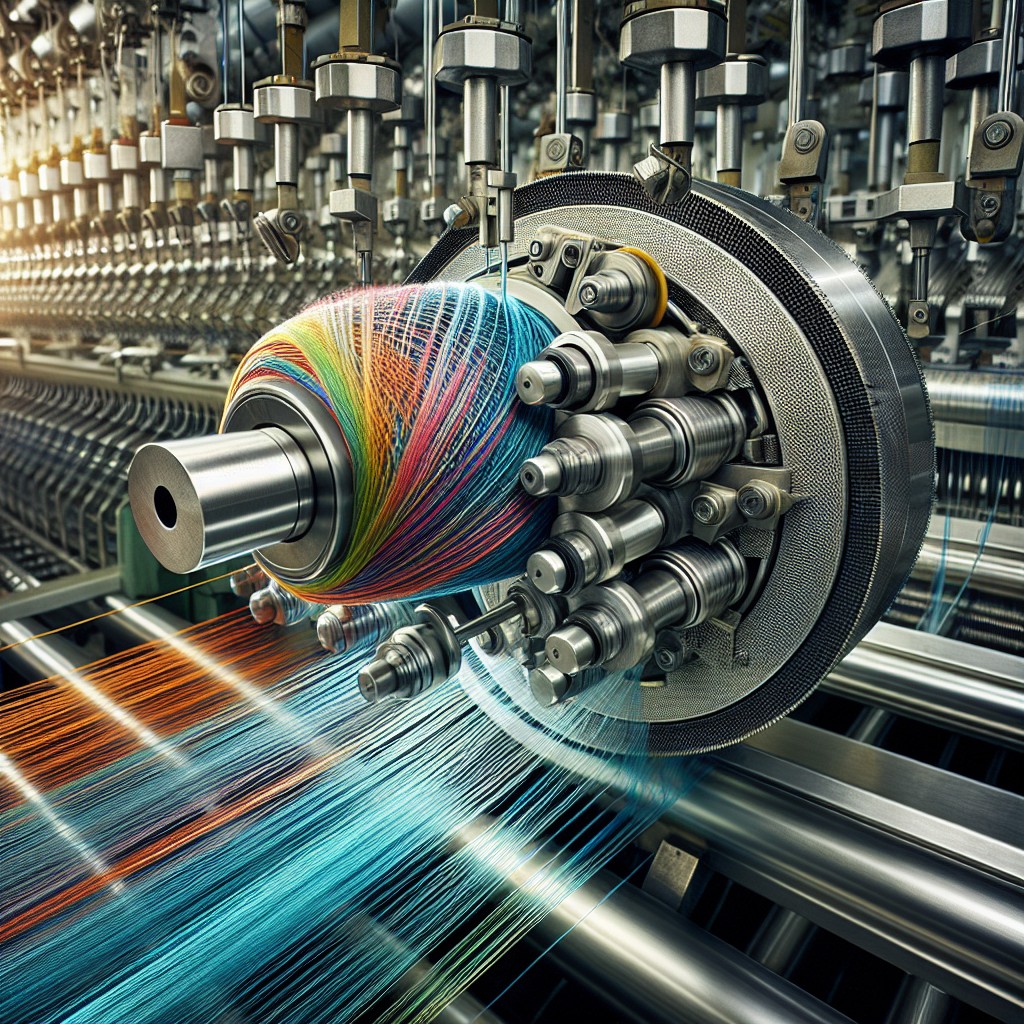

Tensioning Systems for Textile Production

These systems can be mechanical or electronic and vary depending on the type of machine being used. In knitting machines, for example, tensioners are used to regulate the amount of yarn being fed into each needle.

Similarly, in weaving machines, warp tensioners help maintain an even distribution of tension across multiple threads.

While these types of industrial-grade tensioning systems may not be necessary for home crafting projects like crocheting or knitting scarves and hats; understanding how they work can give you a better appreciation for how important proper yarn tension is to producing high-quality textiles.

Cost of Yarn Tensioners

The price of a yarn tensioner can vary depending on the type and brand you choose. Spring tensioners are typically the most affordable option, while hysteresis and gate/storage tensioners tend to be more expensive due to their advanced features.

However, it’s important not just to focus on the upfront cost but also consider long-term value. Investing in a high-quality yarn tensioner may save you money in the long run by reducing waste from tangled or unevenly-tensioned yarns.

Ultimately, finding the right balance between affordability and quality will depend on your individual needs as well as your budget.

20.2 Yarn Tensioner Technologies

One such advancement is the 20.2 yarn tensioner technology, which uses a combination of mechanical and electronic components to regulate yarn tension with precision.

This type of yarn tensioner features an advanced control system that can be programmed to adjust the amount of force applied to the yarn based on specific parameters such as speed or diameter. The result is consistent stitch formation throughout your project, regardless of changes in material thickness or other variables.

The 20.2 technology also offers real-time monitoring capabilities that allow you to track your progress and make adjustments on-the-fly if necessary. This feature can be particularly useful for larger projects where small variations in stitch size could add up over time.

Deepwater Tensioning Differences

While this may seem unrelated to yarn crafts, there are some similarities between deepwater tensioning and yarn tensioners that can be useful for crafters.

One key difference between deepwater and surface-level yarn tensions is that deepwater tensions must withstand much greater forces due to water pressure. This means that they need to be made of stronger materials and designed with more robust mechanisms than typical yarn tensioners.

However, despite these differences, there are still lessons we can learn from deepwater technology when it comes to designing effective yarn tensioners. For example, both types of systems require precise control over their respective forces in order for them to function properly.

5.2.6 Textile Tensioners Explained

One type of textile tensioner that has gained popularity in recent years is the 5.2.6 textile tensioner, which offers a unique design that allows for greater control over yarn tension.

The 5.2.6 textile tensioner works by using a series of rollers to regulate the amount of yarn fed into your project, ensuring that it remains at a consistent level throughout your work.

One advantage of this type of yarn tensioner is its ability to handle different types and weights of yarn with ease, making it ideal for those who like to experiment with different materials in their projects.

Another benefit is its compact size and portability, allowing you to take it on-the-go or store it easily when not in use.

Tensioner Stroke/Telescopic Joint (TJ) Stroke Limits

This refers to how far the tensioner can move in order to regulate the amount of tension on your yarn. Different types of yarn tensioners have different TJ stroke limits, so it’s important to choose one that will work well with your particular project.

For example, if you’re working on a large knitting project that requires a lot of movement and flexibility from your hands and arms, you may want a yarn tensioner with a larger TJ stroke limit. On the other hand, if you’re working on something smaller or more delicate like lacework or embroidery, then a smaller TJ stroke limit may be sufficient.

Ultimately, choosing the right type of yarn tensioner for your needs will depend on several factors including what type of craft you are doing and how much control over your stitches’ consistency is required. By considering all these factors carefully before making any purchase decisions about which kind(s) best suit(s) their individual needs as knitters/crocheters/weavers/etc., people can ensure they get exactly what they need without overspending unnecessarily!

FAQ

What is yarn tensioner?

A yarn tensioner is a device, such as KARL MAYER’s, that maintains consistent yarn tension across a warp’s length and width while providing gentle treatment and handling high-speed or aggressive yarns.

What is additive tensioner?

An additive tensioner is a device that adds a constant tension to the input tension, such as a disk-tension device, with the formula To = Ti + 2 μW for calculating the added tension.

What is a tensioning device?

A tensioning device, or tensioner, is a mechanism that applies force either parallel or perpendicular to produce or maintain tension in various applications, such as hydraulic bolt tensioners or spring-loaded bicycle chain tensioners.

What is a tension device in textile?

A tension device in textile is a tool used to control the tension of the yarn, preventing irregular, thick, or thin yarns from breaking down due to over tension.

How do yarn tensioners improve the knitting or weaving process?

Yarn tensioners improve the knitting or weaving process by maintaining consistent tension on the yarn, enabling smoother and more even fabric production.

What are the different materials used to construct yarn tensioners?

Yarn tensioners are constructed from various materials, including plastic, ceramic, and metal.

Can yarn tensioners be adjusted to accommodate different yarn types and thicknesses?

"Yes, yarn tensioners can be adjusted to accommodate different yarn types and thicknesses."