Discover the various types of yarn creels used in textile manufacturing, as we unravel their unique features and applications in today’s industry.

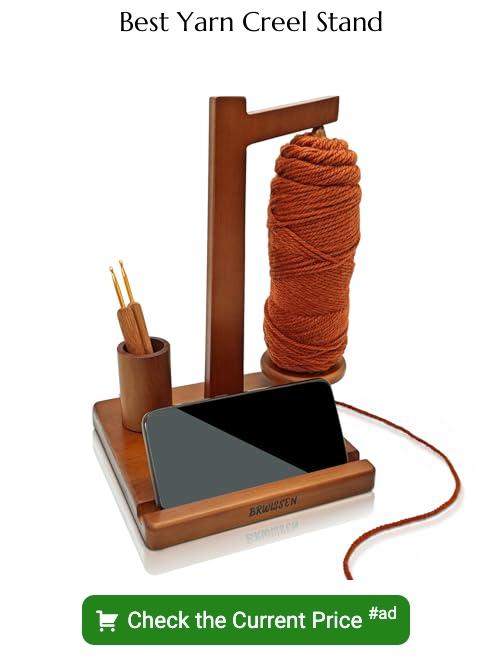

Are you a yarn enthusiast? Do you love experimenting with different types of yarn and creating beautiful crafts? If so, then you must be familiar with the importance of a good quality yarn creel. A yarn creel is an essential tool for any knitting or crocheting project as it helps to hold and feed the yarn smoothly.

But did you know that there are different types of yarn creels available in the market? Each type has its unique features and benefits, making it suitable for specific projects. In this article, we will explore the various types of yarn creels and help you choose the perfect one for your next project.

So, grab your favorite cuppa, sit back, relax, and let’s dive into the world of yarn creels!

Types of Yarn Creels

The unwinding creel is one of the most common types of yarn creels used in textile manufacturing. It is designed to hold and feed yarn from a large package or cone smoothly.

The unwinding creel consists of several spindles arranged vertically, with each spindle holding a single package or cone.

One significant advantage of using an unwinding creel is that it allows for continuous production without frequent stops to change packages. This type of yarn creel also helps prevent tangling and knotting, ensuring smooth operation throughout the entire process.

In addition to its use in textile manufacturing, an unwinding creel can also be useful for home-based knitting projects where multiple colors are required simultaneously. By using this type of yarn holder, you can easily switch between different colored cones without having to stop your work frequently.

Definition of Creel

It is an essential tool for any knitting or crocheting project, as it helps to maintain the tension of the yarn while working on a project. A typical creel consists of several spindles arranged vertically or horizontally, depending on the type of machine being used.

The number of spindles can vary from just a few to hundreds, depending on the size and complexity of the machine.

Creels are made from various materials such as wood, metal or plastic and come in different shapes and sizes based on their intended use. Some creels are designed for unwinding filament yarns while others are meant for staple fibers like cotton wool.

Unwinding Creels

As the name suggests, these creels are designed to unwind and feed yarn from a stationary position. They consist of a series of spindles or cones that hold the yarn in place while it is being unwound.

Unwinding Creels come in various sizes and configurations, depending on their intended use. Some models have multiple levels or tiers to accommodate different types and colors of yarn, while others may be designed for specific applications such as weaving or knitting.

One advantage of using an Unwinding Creel is that it helps maintain consistent tension throughout the entire length of the yarn. This ensures that your finished product has an even texture without any loose spots or knots.

When selecting an Unwinding Creel for your project, consider factors such as size, capacity, ease-of-use and compatibility with other equipment you may already own.

Creels for Staple Fibre

Creels used for staple fibre have to be designed in such a way that they can hold and feed the yarn without tangling or breaking it. These creels usually have multiple levels, with each level holding several bobbins of yarn.

One popular type of creel used for staple fibre is the horizontal creel. This type of creel has a series of rods arranged horizontally, with each rod holding several bobbins.

The rods rotate as the machine operates, allowing the bobbins to unwind smoothly.

Another common design is vertical stapler cradles which are often found in spinning mills where large quantities need to be processed at once; these cradles allow easy access and quick changeover between different types or colors.

Creels for Filament Yarns

These yarns require a different type of creel as compared to staple fiber creels. The filament yarn creel is designed to hold the spools or cones containing the continuous filaments and feed them into the machine at a constant tension.

The most common types of filament yarn creels include vertical, horizontal, and inclined positioners. Vertical positioners allow easy access to each individual spool or cone while minimizing tangling between threads.

Horizontal positioners provide better control over thread tension by allowing gravity to assist with feeding the filaments through guides and rollers.

Inclined positioners offer an alternative solution for larger machines where space is limited but still require precise thread placement during production runs.

Choosing the right type of filament yarn creel depends on several factors such as machine size, number of threads required per run, desired speed output, among others.

Yarn Tensioners

They help to maintain a consistent tension on the yarn, ensuring that it feeds smoothly and evenly through the machine. Yarn tensioners come in various types, including mechanical and electronic versions.

Mechanical tensioners use springs or weights to apply pressure on the yarn as it passes through them. These types of tensioners are simple but effective and can be adjusted easily by changing the spring or weight.

Electronic tensioners use sensors to detect changes in the yarn’s speed and adjust accordingly, providing precise control over tensions throughout production runs.

Choosing a suitable type of Yarn Tensioner depends on several factors such as fiber type, denier count (thickness), winding speed required for your project among others. It is important to consider these factors when selecting a suitable one for your project so that you can achieve optimal results with minimal effort.

Yarn Stop Motions

It works by stopping the machine when it senses an issue, preventing further damage to the fabric and saving time and resources. Yarn stop motions are essential for textile manufacturing as they ensure consistent quality throughout production.

There are different types of yarn stop motions available, including mechanical and electronic ones. Mechanical stops work by using a spring-loaded mechanism that detects changes in tension caused by broken or tangled threads.

Electronic stops use sensors to detect changes in light transmission through the thread path.

If you’re looking for smooth knitting or crocheting experience with minimal interruptions due to broken threads, then investing in a good quality creel with built-in yarn stop motion is crucial!.

FAQ

What is a yarn creel?

A yarn creel is the location where yarns are arranged either on or off the knitting machine to enable yarn delivery to the knitting cycle.

What is a creel in textiles?

A creel in textiles is a frame used for holding the feeding thread or yarn bobbin, often equipped with a tensioning device for maintaining proper tension during the manufacturing process.

How many types of warping are there?

There are 5 types of warping processes: direct warping, indirect warping, section warping, beam warping, and warping creel.

What are the parts of a Creel?

The parts of a Creel include the package holder, slub catcher, tensioner, and compensator.

What are the different types of yarn creels used in the textile industry?

Answer: The different types of yarn creels used in the textile industry include stationary, travelling, and overhead creels.

How does a creel contribute to the efficiency of yarn production in textiles?

A creel contributes to the efficiency of yarn production in textiles by holding multiple yarn packages in place, enabling smooth and simultaneous unwinding during the manufacturing process.

What factors should you consider when choosing the right type of creel for a specific application?

When choosing the right type of creel for a specific application, consider factors such as tension control, yarn tension, and yarn storage requirements.