Discover the fascinating world of yarn printing machines as we delve into various types and their unique capabilities in this informative blog post.

Are you a yarn enthusiast looking to add some unique prints to your collection? Or maybe you’re a textile manufacturer searching for the perfect machine to create stunning patterns on your yarns. Whatever your reason may be, understanding the different types of yarn printing machines available in the market can help you make an informed decision.

From traditional screen printing machines to modern digital printers, there are various options out there that cater to different needs and budgets. In this article, we’ll explore some of the most popular types of yarn printing machines and their features, so you can choose the one that suits your requirements best.

So grab a cup of tea and let’s dive into the world of yarn printing!

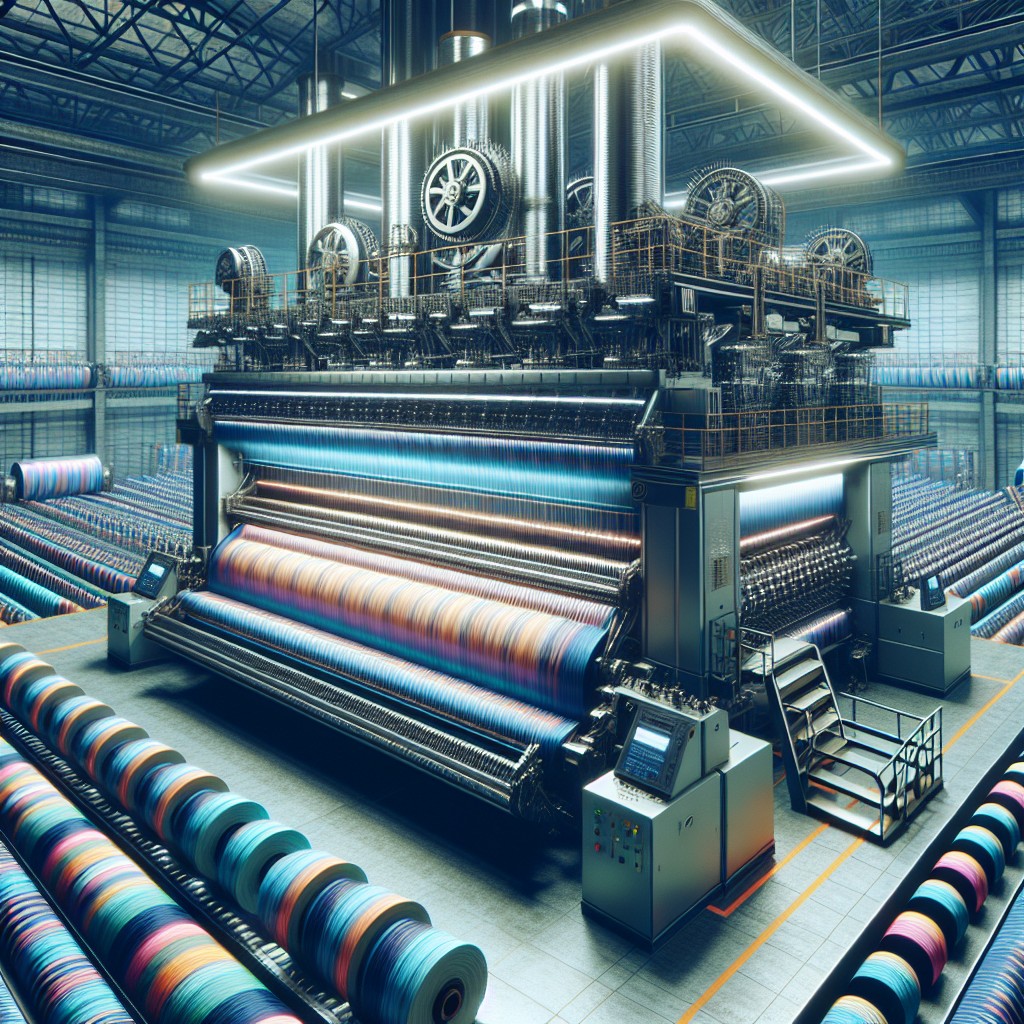

Smart Yarn Printing Machine

In recent years, the textile industry has seen a significant shift towards automation and digitization. Smart yarn printing machines are one such example of this trend.

These machines use advanced technologies like artificial intelligence (AI) and machine learning to create intricate patterns on yarns with high precision.

Unlike traditional printing methods that require manual intervention at every step, smart yarn printers can operate autonomously once they’re programmed with the desired design. They can also detect errors in real-time and make adjustments accordingly, reducing wastage and improving efficiency.

Moreover, these machines offer a wide range of customization options for designers to experiment with different colors, textures, and patterns without any limitations. With their ability to produce complex designs quickly while maintaining consistency across batches makes them an ideal choice for large-scale production units.

Yarn Dyed Fabrics

Yarn dyed fabrics are created by first dyeing individual yarns in different colors before weaving them together into a fabric. This process creates a unique look that cannot be achieved with other printing methods.

There are two main types of yarn-dyed fabrics: woven and knit. Woven fabrics, such as plaids or stripes, are made by interlacing vertical (warp) and horizontal (weft) threads on a loom.

Knit fabrics, on the other hand, use loops instead of interlacing threads.

Yarn dyed fabric can be used for various purposes like clothing items such as shirts or dresses; home decor items like curtains or tablecloths; accessories like scarves or bags etc.

Fully Automatic PLC Control Machines

These machines use programmable logic controllers (PLCs) to automate various tasks, such as yarn feeding, tension control, and printing speed adjustment. With the help of sensors and other advanced technologies, these machines can detect any errors or malfunctions in real-time and make necessary adjustments automatically.

One of the biggest advantages of fully automatic PLC control machines is that they require minimal human intervention. This means that operators can focus on other important tasks while the machine takes care of printing high-quality patterns on yarns consistently.

Moreover, these machines offer a high degree of customization options when it comes to pattern design and color selection. Manufacturers can easily upload their designs onto the machine’s software interface using USB drives or Ethernet connections.

Ring Spinning Machine

It’s a staple for producing high-quality yarns that are strong, durable, and have excellent uniformity. The process involves feeding fibers through rollers to create a sliver or roving which is then spun into yarn by twisting it with a spindle and ring.

This type of machine has been around for centuries but has undergone significant improvements over time to increase efficiency and productivity. Modern ring spinning machines can produce up to 500 meters of yarn per minute!

Splitting And Striping Warping Machine

This machine allows you to split the yarn into multiple strands, which can then be dyed in different colors or shades. The stripped yarns are then rewound onto bobbins, ready for weaving or knitting.

One of the advantages of using this type of warping machine is that it allows you to create complex designs with ease. You can experiment with different color combinations and stripe widths until you find the perfect pattern for your project.

Another benefit is that it saves time compared to manual methods such as hand-painting or tie-dyeing each strand separately. With a splitting and striping warping machine, you can produce large quantities of striped yarn quickly and efficiently.

HJW408 Weaving Machine

This advanced machine can produce various types of fabrics, including plain weave, twill weave, and satin weave. It features an electronic let-off system that ensures consistent tension throughout the weaving process for uniform fabric quality.

The HJW408 also has a user-friendly interface that allows operators to easily adjust settings such as speed and tension according to their needs.

With the help of this state-of-the-art weaving machine, textile manufacturers can create intricate patterns on their yarns with ease. Whether you’re looking to produce delicate lace or sturdy denim fabric, the HJW408 has got you covered! Its ability to handle different types of yarns makes it an ideal choice for creating unique designs using various materials.

Investing in a high-quality weaving machine like the HJW408 can significantly improve your production capabilities while ensuring consistent quality output every time.

New Denim Cotton Yarn Recycling Machine

The new denim cotton yarn recycling machine is a perfect example of this trend. This innovative machine can take old denim fabric and turn it into high-quality cotton yarn that can be used in various applications.

The process involves shredding the old denim fabric into small pieces, which are then fed through the recycling machine. The fibers are separated from any impurities or contaminants, leaving behind pure cotton fiber that is ready to be spun into yarn.

This technology not only reduces waste but also saves energy by eliminating the need for virgin raw materials. It’s an excellent option for companies looking to reduce their carbon footprint while still producing high-quality products.

As we have seen in this article so far, there are various types of machines available in today’s market catering to different needs and budgets when it comes to printing on yarns or creating unique patterns on them.

Continuous Hank Yarn Roller Printing Dyeing Machine

This machine uses rollers that apply pressure on the yarn as it passes through, ensuring even distribution of color or pattern. The continuous process saves time and reduces waste compared to traditional batch dyeing methods.

One of the advantages of this machine is its flexibility in handling different types of fibers, including cotton, wool, silk, and synthetic materials. It can also handle various counts (thickness) of yarns without compromising quality.

Another feature that makes Continuous Hank Yarn Roller Printing Dyeing Machine stand out is its precise temperature control system. Temperature plays a crucial role in achieving consistent results when printing or dyeing yarns; hence this machine has sensors that monitor temperature levels throughout the process.

High Temperature Fiber Dying Mini Cone Space Sectional Secondhand Machine

This machine uses high-temperature steam to dye fibers, ensuring that the color penetrates deep into the material for long-lasting results. The mini cone space design allows for easy loading and unloading of materials, while the sectional feature ensures even distribution of heat throughout each section of the machine.

While this type of machine may be secondhand, it still offers excellent performance and reliability when properly maintained. It’s an affordable option for small businesses or those just starting out in textile manufacturing who want to invest in quality equipment without breaking their budget.

Whether you’re looking to create vibrant yarns with unique patterns or produce high-quality fabrics with consistent colors, a High Temperature Fiber Dying Mini Cone Space Sectional Secondhand Machine can help you achieve your goals efficiently and effectively.

FDY PP Multifilament Yarn Machine

This machine uses polypropylene as the raw material, which is melted and extruded through spinnerets to form continuous filaments that are then wound onto bobbins. The resulting yarn has a smooth texture, making it ideal for use in various applications such as weaving, knitting, and sewing.

One of the advantages of using FDY PP multifilament yarns is their resistance to abrasion and chemicals. They are also lightweight yet strong enough to withstand heavy loads without breaking or stretching out of shape.

These yarns have good color fastness properties that make them suitable for dyeing in different shades.

Different Types of Textile Dyeing Machines

Some of the most popular types of textile dyeing machines include jet dyeing machine, beam dyeing machine, jigger dyeing machine, and winch dyeing machine.

Jet Dyeing Machine: This type of machinery is ideal for high-speed processing as it uses a continuous flow system. The fabric or yarn passes through a series of nozzles where the dyes are injected under high pressure.

Beam Dye Machine: Beam dyers use large beams that hold several hundred kilograms worth of fabric or yarn at once. These beams rotate slowly while being immersed in hot water containing dyes.

Jigger Dye Machine: Jiggers work by passing fabrics through vats filled with hot water and dyes repeatedly until they reach their desired color intensity level.

Winch Dye Machines: Winches operate similarly to jiggers but on a smaller scale. They’re perfect for small batches or samples as they can handle only limited amounts at once.

Each type has its unique features that make them suitable for specific applications such as batch size requirements, speed requirements among others. Understanding these differences will help you choose which one best suits your needs when looking into purchasing one for your business operations.

FAQ

What machine makes yarn?

Answer: The machine that makes yarn is called cotton-spinning machinery, which processes prepared cotton roving into workable yarn or thread.

How many types of printing machines are there?

There are 8 main types of printing machines in use today.

What are the different types of screen printing machines?

Answer: The three common types of screen printing machines are flat-bed, cylinder, and rotary presses.

How many types of dyeing machines are there?

There are four types of dyeing machines according to textile material: Fiber dyeing machine, Yarn dyeing machine, Fabric dyeing machine, and Garment dyeing machine.

What are the main components of a yarn printing machine?

The main components of a yarn printing machine include dyeing devices, printing units, drying chambers, and winding mechanisms.

How has technology impacted the development of yarn printing machines?

Technology has significantly enhanced yarn printing machines’ efficiency, precision, and versatility, enabling intricate designs, reduced waste, and faster production times.

What factors should be considered when choosing a yarn printing or dyeing machine?

Answer: When choosing a yarn printing or dyeing machine, consider factors such as machine type, processing capacity, dyeing method, energy-efficiency, automation level, and ease of maintenance.